Artificial intelligence has gained prominence the last few years, but there’s a huge elephant in the room: What should packaging companies do with it? As more businesses demonstrate use cases for the technology in packaging and beyond, AI is moving from buzzy jargon to a more widely used tool, in part to track what happens to packaging down the line.

Rebecca Hu, CEO at recycling AI and robot startup Glacier, explained during educational sessions at the Packaging Recycling Summit last week how her company's vision-based AI technology helps to sort recyclable packaging at the MRF level. She also pointed out how the insights gleaned from AI technology help brands design and tweak their packaging in ways that boost the likelihood of it being recycled at its end of life.

For instance, Glacier partnered with Colgate-Palmolive and a New Jersey MRF to build a first-of-its-kind AI model, for use with MRFs’ optical scanners, to detect and characterize toothpaste tubes based on their materials and recyclability. Colgate had introduced an HDPE tube in 2022 that it said was recyclable curbside, and others have followed suit, but many of the tubes making their way into MRFs still are not considered recyclable with existing infrastructure.

Glacier believes its technology will improve capture rates. The company is “excited about these types of AI results that we've seen from our partnership with Colgate, and we're already expanding this type of work and this technology to additional MRFs in new geographies across the country,” Hu said.

In the tube example, Colgate could see data on a dashboard indicating the proportion of tubes in single-stream recycling that are for toothpaste and how tube recycling behavior varies from city to city. Hu said this demonstrates the technology’s relevance for improving business operations. “This type of AI is going to be broadly applicable to all of us,” she said.

Simply collecting data is not enough. Using AI to develop insights and drive actions is key, speakers said.

“We're collecting so much data continuously on what's coming through this MRF and other MRFs across the country. What's important, though, is not just a data dump of images,” Hu said. “The real power behind this type of AI data is the ability to provide really, really easily digestible data and easily actionable insights in a real-time feedback loop.”

During a separate educational session, Matthew Wright, CEO of specification management company Specright, described how technology advancements help to transform manufacturers’ data use and eliminate challenges with siloed data across a company.

“If data's in different spots and it's not connected, it's not actionable, it's not reportable and it's not trustworthy,” he said.

Sustainability is one area that he believes could benefit from digitized data systems. Collecting, managing and reporting sustainability data can be done more efficiently and effectively with digitized specification data systems, which incorporate AI, he explained. Using a flexible technology helps businesses keep up with the rapidly evolving sustainability landscape.

“We have to be so flexible in our data structure and the way we build our data structure, because the concepts of sustainability are going to be dramatically different in five years from now. What we think is great today, or might be good or aspirational today, might be evil and bad in five years from now,” Wright said.

Artificial intelligence can be used in combination with a variety of technologies, but it’s currently showing promise in MRF settings. In a separate MRF AI example, Rumpke Waste & Recycling said during another conference session that AI is the force behind its decision to start accepting thermoforms in curbside recycling on Nov. 1. Jeff Snyder, senior vice president of recycling, called AI a “game changer” for operations at Rumpke’s new MRF in Columbus, Ohio, and said coupling it with a near infrared optical scanner enables the segregation and capture of more materials.

In another partnership, Glacier worked with Amazon to train AI to identify items that aren’t yet prevalent in the materials stream — biobased plastics — and use that knowledge to improve packaging design for better traceability and recoverability once the use of those items scales.

Prior to the partnership, Amazon had limited traceability of its packaging down the supply chain and couldn’t verify it was getting recycled, said Nicholas Ellis, principal at Amazon Climate Pledge Fund.

“Previously, we knew that we could use biobased materials, put them into certain packaging applications, ship them to customers and they get collected, sorted, recycled — and then we largely lose the plot. We might not know what happened to that box, if it really got recycled in the way we wanted,” Ellis said.

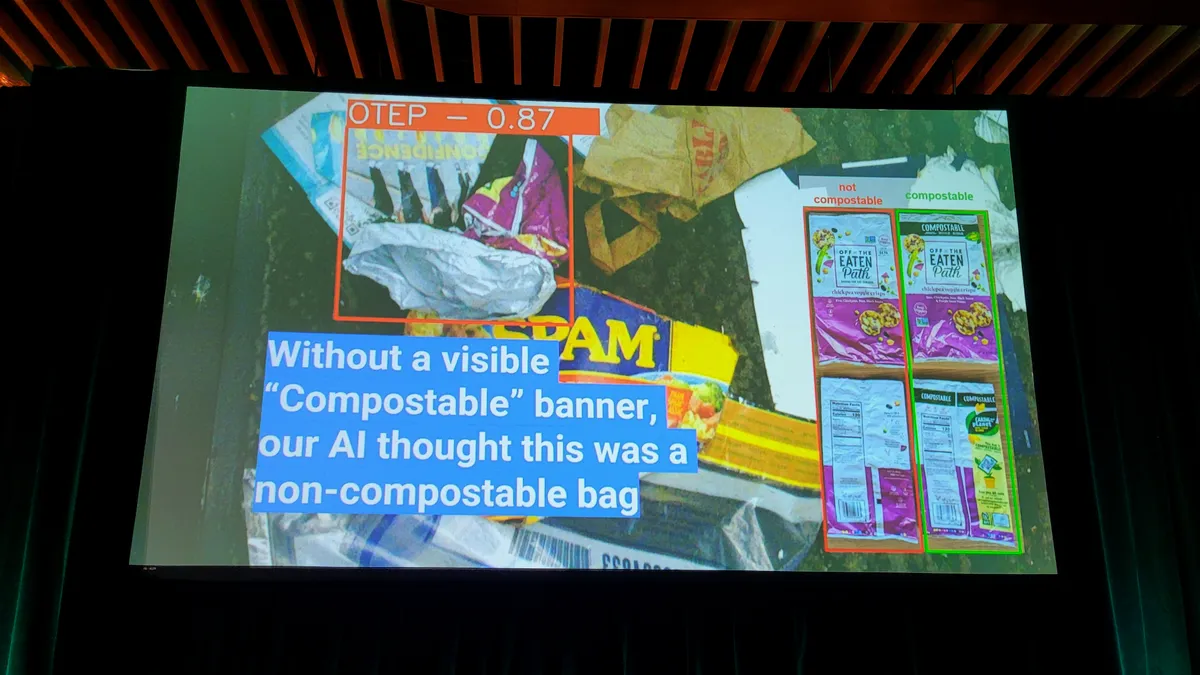

So Amazon worked with Glacier to create “greater accountability for that package as it moves,” he said. This occurred via Glacier building a “first-of-its-kind AI model” to identify at a MRF certain types of bioplastic plastic packaging — a variety of SKUs including snack bags, produce bags, shopping bags and compostable packaging — Hu said.

Training AI to pick out bioplastics at a MRF is particularly challenging because to the naked eye those materials tend to look like conventional plastics, she said.

“After several months of collaborating with Amazon, it worked. We were able to develop an AI model that actually got to over 90% efficiency at detecting those packaging formats,” according to Hu. Beyond simply detecting a certain material, “we are actually interested in knowing what are the dimensions that make something easy or difficult to detect, because that's going to inform how we think about improving and innovating on our packaging design going forward.”

The partners found that the size of a packaging item matters in vision-based AI’s ability to detect it, as does the size of the print or distinguishing features on the item. For instance, if a font is too small, the technology can’t read labeling that says “compostable” or “recyclable” — which prompted Amazon to increase its font size. Consistency of design and differentiation of messaging on the packaging also matters.

While the Packaging Recycling Summit was the first major forum in which Glacier and Amazon publicly discussed their findings, the partners are looking at the best avenues to more broadly publicize the lessons for others to learn from as well.

“AI really is an incredible and very new tool that everyone in this room has at their fingertips or in their new arsenal,” Hu said. “We're actively looking for ways to build the features that allow the AI to surface the type of information that we can all actually use and act on.”