Dive Brief:

- Illinois-based startup Chang Robotics announced this month it developed GOEco, a graphene oxide material intended to serve as a safer barrier layer for paper packaging, compared with PFAS.

- Graphene oxide is a carbon-based material that works well with a variety of fiber packaging types, and it does not affect recyclability or compostability, said Timothy Wei, chief scientist for Chang Robotics. “That’s actually one of the big considerations and selling points. ... It’s really kind of the magic sauce,” he said.

- Chang Robotics is arranging production trials with packaging companies, including a food ware manufacturer, which it expects to begin in the first quarter next year. It’s also working to get necessary FDA authorizations for GOEco.

Dive Insight:

Attention to PFAS, the so-called “forever chemicals,” has ramped up in the last eight years or so, Wei said, but safer alternatives are lacking. “The industry doesn't really have a good alternative yet, because those [PFAS] materials actually do a fantastic job of keeping liquid and grease and certain gases from transferring across the boundaries of the food packaging,” he said.

In addition to acting as an alternative to PFAS, GOEco poses as an alternative to multilayer packaging — such as flexibles with paper on the exterior and plastic or foil fused to the inside — that impedes ease of recycling and often ends up in landfills at end of life, Wei said.

Wei was leading a food preservation research initiative at the University of Nebraska when he connected with SonBinh Nguyen at Northwestern University, who worked with graphene oxide. They agreed to collaborate on using graphene oxide in food packaging, specifically in fiber substrates. Wei now also has a position at Northwestern in the Chicago area.

Chang Robotics launched as a company in 2017. The business has a supplier for the graphene oxide it uses, and Chang Robotics engineers that material to be suitable as a packaging barrier.

GOEco is applicable for use with many different types of food-contact fiber packaging, including paperboard boxes, flexible produce bags and disposable table ware such as plates, cups and straws, Wei said.

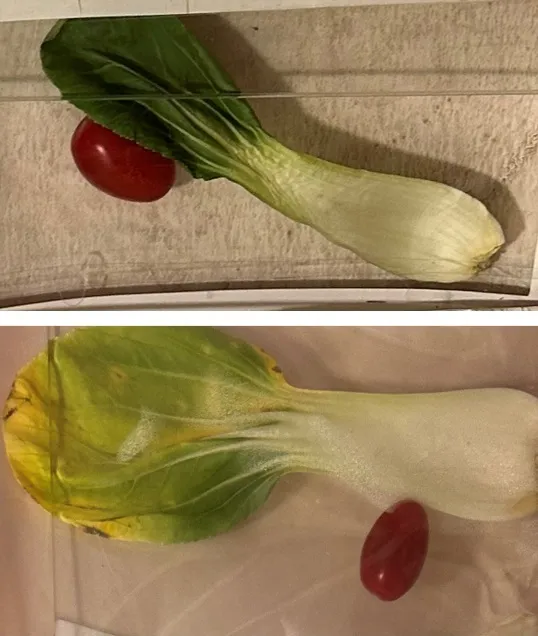

In a series of tests to examine GOEco’s barrier properties, Wei photographed bok choy leaves wrapped in the coated paper vs. leaves wrapped in standard flexible plastic. Over a period of 12 days, the leaves in the GOEco paper showed notably less degradation, illustrating barrier efficacy, he said.

Another series of tests involved observing water and grease absorption of paper plates coated with GOEco. Again, the coating demonstrated effective barrier properties, he said.

Early testing indicated the graphene-based material works as a coating, but in recent months Chang Robotics has had success with blending it into pulp so it is incorporated throughout the packaging. Graphene oxide “has an affinity to the cellulose fibers in paper,” meaning it creates a chemical bond to the paper and “becomes an integral part of the packaging,” Wei said. That also means the barrier material won’t come off the packaging during food contact, although graphene oxide is safe for consumption, he explained.

Chang Robotics engineers are confident that mixing the material with pulp makes the fiber substrate stronger, thus allowing a manufacturer to use less pulp, Wei said. The material reduction enhances sustainability while keeping costs in check, he said. Ensuring affordability has been a driving principle during product development.

“We want to make sure that we don't increase costs. If anything, we would like to reduce the cost of making the packaging,” Wei said. “There really isn't [a barrier] out there yet that's affordable and safe that will allow you to have the same performance as plastic and PFAS.”

Chang Robotics believes the fastest way to get GOEco to market is to license the technology to paper and packaging producers.

“We’re trying to do a social good,” Wei said. The business is tackling how to “make this broadly available, because we're really trying to solve a major societal environmental problem.”

Other companies also are working to develop PFAS-free packaging barriers or papers. Nordic Paper offers an uncoated base paper alternative and Solenis’ TopScreen uses alternative chemicals to form a double or single coating. And J&J Green Papers developed an organic, plastic-free barrier, which it calls Janus, primarily derived from rice plants.

Besides developing GOEco, Chang Robotics does engineering and robotics innovation work for sectors including manufacturing, government technology and healthcare.