The U.S. Department of Energy plans to invest in long-term research and development to improve existing plastic recycling technologies and invent new methods it hopes will cut U.S. energy consumption and prevent pollution.

The DOE recently published its Strategy for Plastics Innovation report, which calls for advancing certain chemical recycling technologies and improving mechanical recycling. It also calls for doing more with biodegradable and bio-based plastics technology and approaching R&D projects with a more intentional environmental justice focus.

With demand for plastics expected to remain high in coming years, the report frames the priorities as a way to more responsibly produce and manage existing plastic while developing “new classes of plastic that are recyclable and upgradeable by design.”

The report is an update to the agency’s 2019 Plastics Innovation Challenge, an initiative meant to make plastic recycling more economically viable. Plastic industry groups including the American Chemistry Council and PLASTICS have applauded the initiative; some environmental groups, like Beyond Plastics, have criticized the DOE’s recent investments in this approach, saying more effort should go into eliminating plastics altogether.

The DOE’s goal is to develop technologies that can “address the end-of-life fate” for more than 90% of plastic materials. It also wants to cut in half the amount of energy used to create plastics.

The Energy Department has a stake in plastics recycling and innovation research in part because plastics production can be an energy-intensive process. About 2% of total energy consumption in the United States is used for manufacturing plastics, and virgin plastic production generates about 3.8% of global greenhouse gas emissions, the report states.

More research for chemical recycling

The DOE sees technologies for chemical recycling, which the plastics industry calls advanced recycling, as an ideal candidate for future research. It names numerous “chemical deconstruction” methods, including gasification, pyrolysis, depolymerization and solvent-based strategies, that could benefit from more R&D.

Each of the available methods has merits, but each also has challenges related to feedstock contamination, availability, or preprocessing and sorting needs, it said.

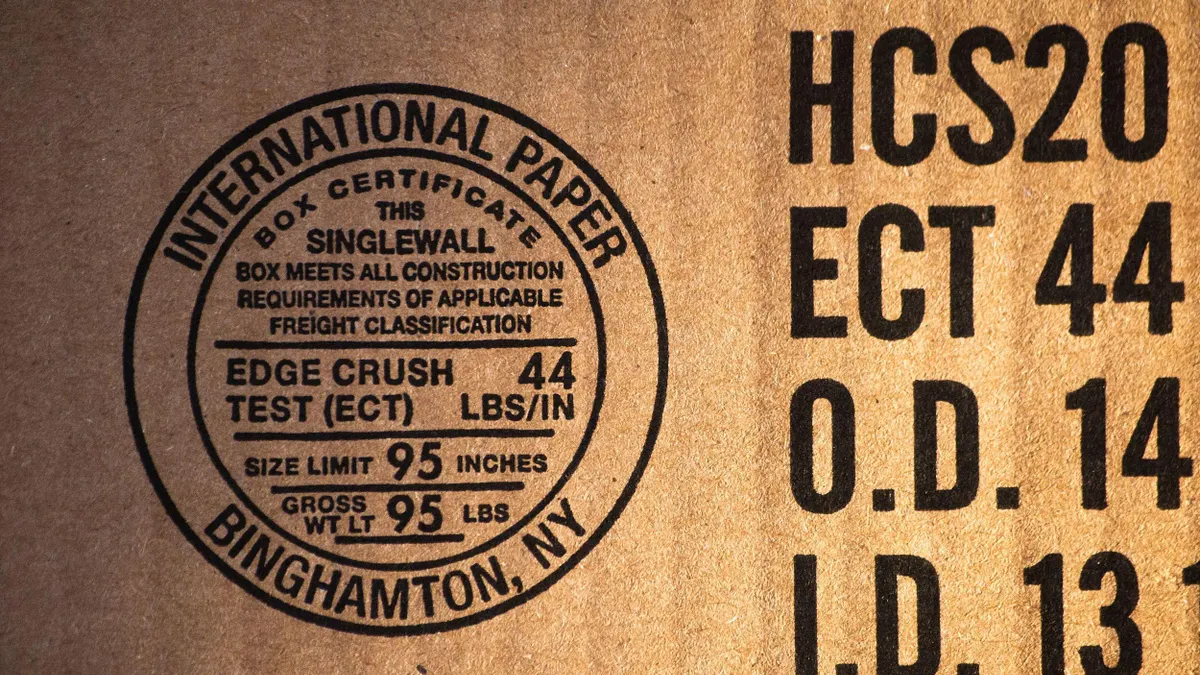

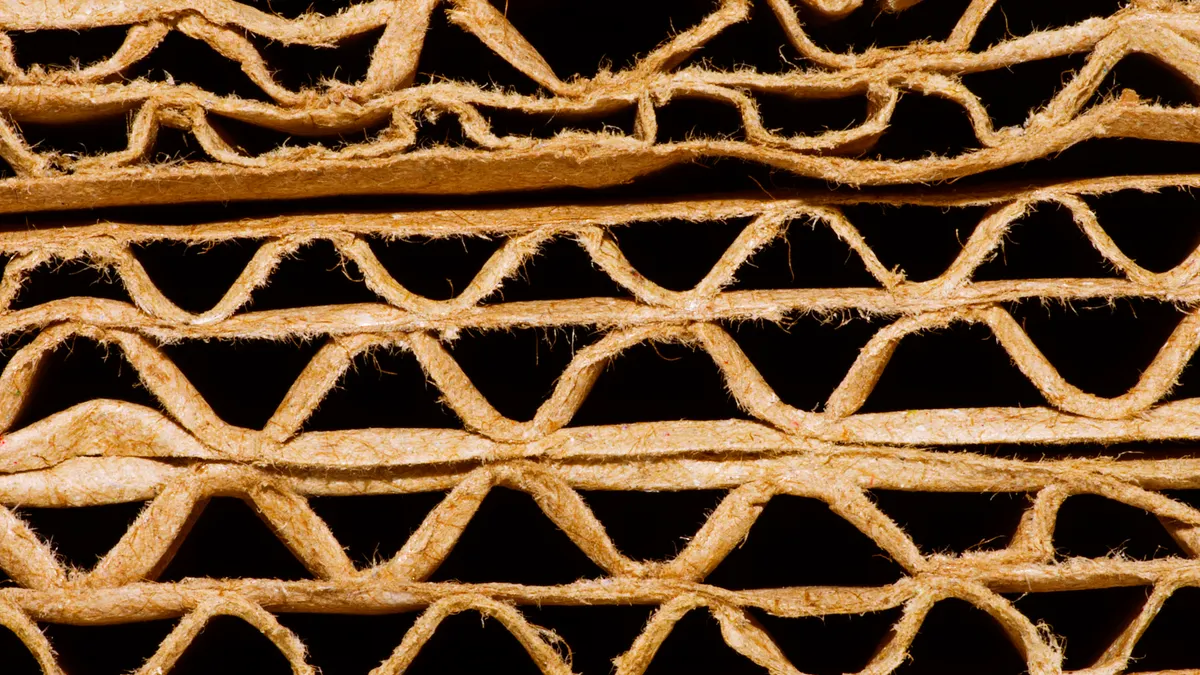

The report specifically names flexible plastic and multilayer packaging as materials that could benefit from additional research. The DOE also thinks it can help recyclers better handle “mixed and contaminated waste streams,” and the report leaves the door open for the invention of even more chemical recycling methods in future years.

However, the DOE report stopped short of naming chemical recycling as the best option for handling plastics, instead recommending a life cycle analysis of each technology to determine how “advantageous” it will be in the long run.

Incorporating environmental justice

Environmental justice advocates have long voiced concerns about chemical recycling’s possible impacts on the environment and on vulnerable populations. In the years since the DOE started the plastic recycling innovation initiative in 2019, the Biden administration has made environmental justice a priority for all federal agencies.

The DOE report makes several environmental justice recommendations for researchers and acknowledges that “there is a long history of disproportionate exposure to pollutants from petroleum extraction and refining to communities of color, leading to excess negative health impacts related directly to industry efforts.”

The report calls for siting of new recycling or material production facilities to be “planned and implemented equitably” and says that community engagement must be a priority throughout the planning process. R&D for plastic design and production must include plans to reduce or eliminate health disparities and “dramatically” reduce or eliminate greenhouse gas emissions, it says.

Jobs created from such technologies should come with “inclusive policies” and workforce development aspects, and any benefits from improved plastic production efforts should go back into disadvantaged communities most impacted by “current plastic lifecycles,” according to the report.

Beyond seeing opportunities in chemical recycling methods, the DOE also hopes to discover new methods for using plastic-degrading enzymes to break down plastics. It also sees merit in creating more bio-based plastics, better packaging design and investments in mechanical recycling technology that can make sortation more efficient and help minimize microplastics.