Companies constantly innovate with technology and redesign their packaging. Here’s a look at five recent examples of product launches, material switches and sustainable packaging solutions on Packaging Dive’s radar.

Put a lid on it

Greece-based food service packaging manufacturer Matrix Pack, known for its paper straws, introduced a line of hot and cold drink lids made from molded fiber. The lids are a plastic alternative that will be available in North America and Europe.

Matrix Pack’s foray into this space is through a licensing agreement with Sweden-based PulPac, which developed the “groundbreaking” dry-molded fiber technology. Matrix said in a news release that dry-molded fiber technology is the “most innovative, lower-cost and energy-efficient alternative to replacing unnecessary single-use plastics with biodegradable, highly recyclable products.” The company said this technology uses 70% less energy and 99% less water than with wet-molded fiber technology.

‘Greener’ greens

Hydroponic farming company Fieldless is also making a switch to fiber. It replaced 90% of the plastic for its lettuce packaging — previously a plastic clamshell — with cardboard that has a resealable plastic film top. Fieldless said in a blog post that the “first-of-a-kind” cardboard base can be recycled once the consumer removes the plastic film top and liner.

“While the small amount of plastic will go to landfills, cardboard has a significantly higher rate of recycling or composting across all the geographies where our products can be purchased,” it said. “There is no perfect solution, and we don’t claim this one is. But it’s significantly better. And we’re extremely proud to be the first company to package cut greens this way.”

Getting on a soapbox

Dr. Bronner’s has switched its Pure-Castile Liquid Soap packaging to fiber cartons, which will reduce plastic use by 82% compared with the company’s plastic bottles of the same size. The cardboard container is solely intended for refilling plastic containers, as it will not withstand repeated use in wet environments like a shower. The company noted in a news release that its plastic bottles are made of 100% postconsumer recycled content.

The carton is made from 69% paper, 5% aluminum and 26% polyethylene; the plastic is for the cap and a thin liner inside the carton to contain the soap. According to the company, a lifecycle analysis showed this is the most sustainable single-use option.

“The paper carton performed the best on every relevant ecological impact measure even when accounting for the recycling rates of each material, nationally,” said CEO David Bronner in the news release.

Breaking down barriers

Pennsylvania-based Pixelle Specialty Solutions launched a line of barrier papers as an alternative to single-use plastic packaging. The coated papers are plastic-free and PFAS-free, and the range of customizable options block grease, oxygen and aromas. The products are approved by the U.S. Food and Drug Administration for direct and indirect food contact, and they also can be used in non-food applications, the company said in a news release.

“As companies around the world implement new policies to remove polyfluoroalkyl substances (PFAS) and replace single-use plastics with more sustainable alternatives, they can leverage Pixelle’s portfolio of barrier chemistries to help achieve their goals,” said Michelle LeMere, vice president of engineered specialties, in the release.

Taking form

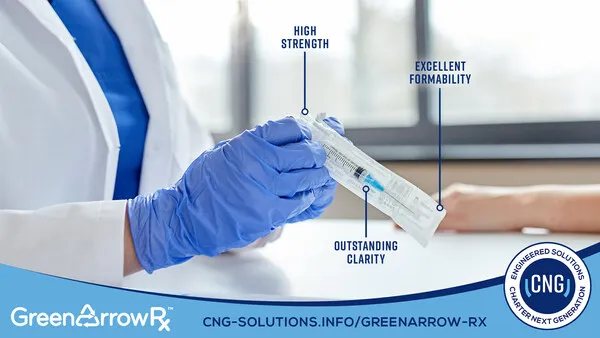

Charter Next Generation introduced a flexible forming film for healthcare that is “built from eco-friendly and readily-available resins,” according to a news release. It says the film helps healthcare companies achieve their sustainability goals and “ease supply issues often associated with traditional resins.” CNG says the forming films, which have a bottom web material and peelable top web, perform as well as those on the market made from other materials.