Companies constantly innovate and redesign their packaging to boost performance, improve marketability and enhance sustainability. Here’s a look at three packaging launches and revamps on Packaging Dive’s radar.

Whey to go

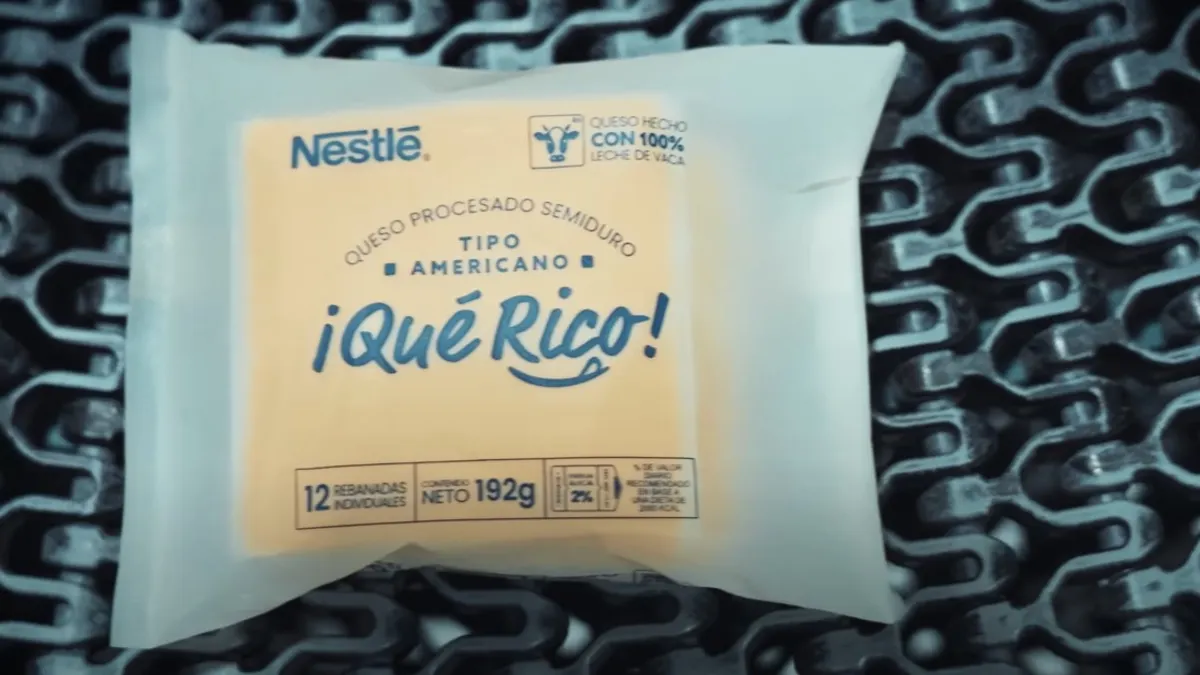

Nestlé Central America partnered with marketing company Ogilvy Colombia to develop packaging for what it calls the first “self-packing” cheese. The bioplastic packaging is made with a byproduct of the cheese production process and eliminates the use of virgin fossil-fuel based plastic.

The wrappers are made from polyhydroxyalkanoate, or PHA, a bioplastic that in this case is derived from whey, a cheesemaking byproduct that has limited commercial uses and is often discarded. The film material has properties similar to conventional plastics, but it biodegrades in 300 days, according to a video from Ogilvy.

The development will help to “transform the way we see and we conceive packaging,” said Kim Waigel, director of communications and corporate affairs for Nestlé Central America, in the video.

Nestlé is testing the bioplastic packaging on its ¡Qué Rico! brand cheeses distributed in Panama.

It’s a miracle!

ProAmpac this week detailed its involvement in ScottsMiracle-Gro’s recent launch of curbside recyclable paper bags for grass seed, clover seed and grass food products, according to a news release. The self-opening paper bags are an alternative to the multilayer plastic film packaging used for many lawn care products.

The multiwall bags have enhanced moisture protection and durability, along with “excellent drop resistance,” according to ProAmpac. They also do not contain PFAS.

“These bags run efficiently in our production process, deliver the durability we need, and align with our focus on environmentally responsible packaging,” said Ray Severa, a packaging engineer at ScottsMiracle-Gro, in the news release.

Taking off layers

SIG is scaling its aseptic carton offerings made without an aluminum layer by introducing a multi-serve version. It says eliminating the metal layer brings the number of main raw materials down to two.

The carton is more than 80% paper and contains biobased polymers. This material provides the same full-barrier protection found in conventional aseptic containers and provides up to 12 months of shelf life, according to a SIG news release. It also runs on existing SIG carton-filling lines.

While aluminum only makes up about 5% of standard aseptic cartons, it accounts for up to 25% of the full-barrier carton’s carbon footprint, according to SIG. The company’s aluminum-free cartons cut the carbon footprint by 61% compared with conventional versions, it says.

Containing fewer layers eases aseptic carton recycling, “only requiring the separation of paperboard and polymers,” Gavin Steiner, chief technology officer at SIG, said in the news release. The company aims to increase the paper content in its aseptic cartons to at least 90%, including closures, by 2030.