Paper cups are for the first time part of the Recycled Materials Association’s materials specifications list, the newest fiber spec since pizza boxes were added in 2020. Graphic Packaging International praised the cups update, calling it “a major milestone in a broader movement to increase awareness and drive greater collection of paper cups in recycling systems,” according to a Monday news release.

ReMa's ISRI specifications set standards for the quality of recycled materials and serve as a guide for scrap material buyers' and sellers' transactions. However, they do not mandate that recyclers must accept certain materials.

“The association's guidelines are highly influential with waste collectors and with thousands of material recovery facilities in deciding what does and doesn't get collected in municipal recycling and collection systems,” explained Graphic Packaging International CEO Mike Doss on Tuesday's earnings call. “This update has particular significance to us,” considering GPI is a major user of recovered fiber and says it’s the largest producer of paper cups in North America.

The company has helped customers develop various paper cup solutions as a plastic alternative, including at food service giants Chick-fil-A and McDonald’s. In the CPG space, GPI helped Nissin Cup Noodles switch from its long-standing foam cup to a fiber version.

Materials and markets

Specs are important because "it means that more material is introduced into the available recycling market," said Bret Biggers, senior economist at ReMa.

ReMa updates its specs on a rolling basis, and it accepts suggestions for new ones from both members and non-members. A ReMa member suggested the paper cups spec in September 2024, according to the association. It took roughly nine months for the suggestion to progress through the various approval phases, including creating a working group of stakeholders, receiving comments and achieving board approval in May.

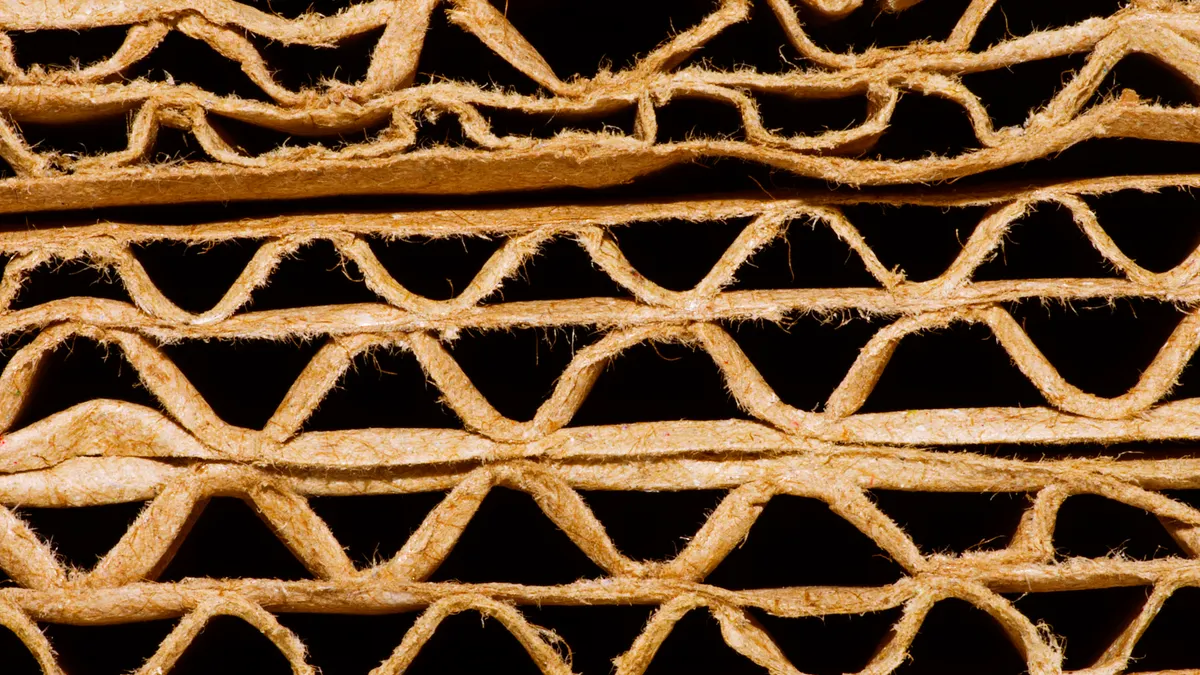

“Most of the paper cups are made with a nice white paper, and it's generally a longer fiber, a higher-quality fiber,” Biggers said. “That's what the industry wants: Good fiber going back into the stream.”

During the process, ReMa also received negative feedback that certain mills prefer not to work with paper cups. Largely, pushback centered on the paper cups' coatings contributing to contamination and making the amount of fiber recovered not worth the hassle. "But the working group overall said that the pros outweigh the cons," Biggers said.

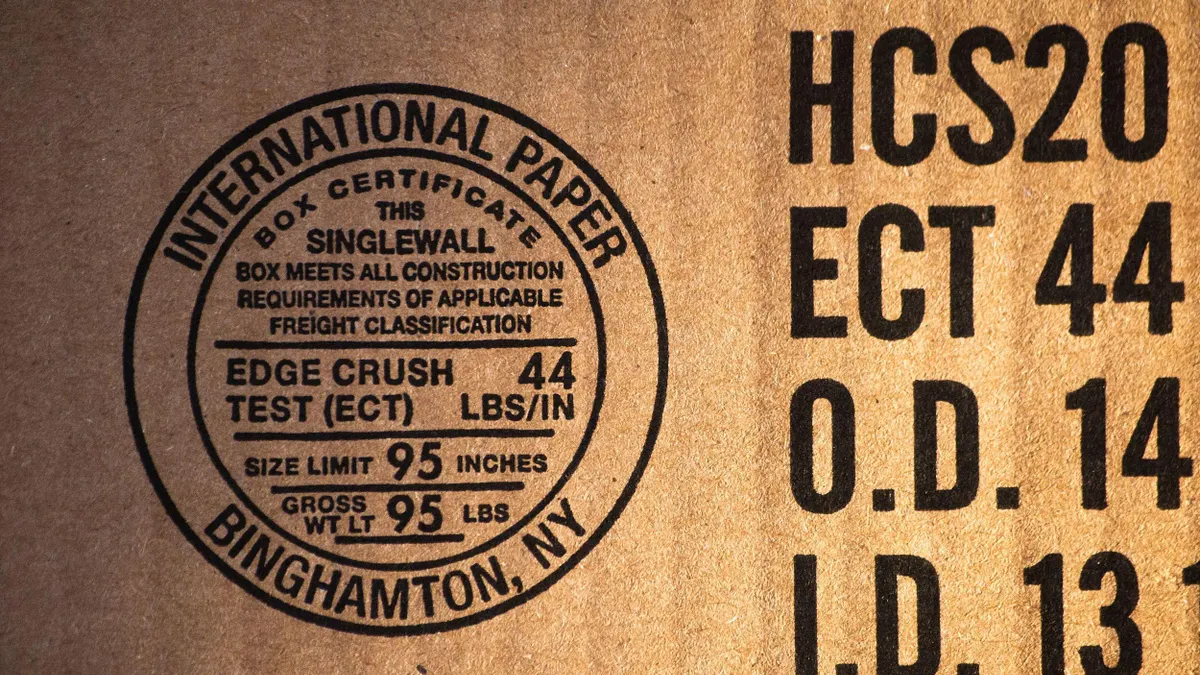

Wood-based fibers usually make up approximately 95% of a paper cup, with thin coatings — mainly plastic — to prevent leaks, according to GPI. Separating the materials has proven challenging for recyclers in the past.

But newer packaging designs are allowing the coatings to separate from the fiber more easily. Plus, technological advances — such as robots and optical sorters at MRFs and modern pulping equipment at mills — now make fiber recovery more efficient.

GPI is on track to open a new recycled paperboard mill in Waco, Texas, in the fourth quarter. It has long touted the capabilities it designed into that facility, such as installing advanced pulping technologies that will allow the company to use fewer coating materials in the paperboard it produces. Plans for Waco also include using up to 15 million paper cups per day as a feedstock.

“We designed Waco to take full advantage of this high quality, underutilized fiber source, which today mostly ends up in landfills,” Doss said Tuesday.

Driving demand

The advances help to drive demand for cup material, sources say. And ReMa's specs “play a key role in end market development,” according to GPI.

Some mills and MRFs still choose not to accept paper cups, and acceptance tends to be regional in nature, Biggers said. “But it's growing, so it's becoming less regionalized,” he explained.

As of mid-2024, more than 40 North American mills — a 33% increase from the prior year — had signed on to accept single-use, polyethylene-coated paper cups, according to the Foodservice Packaging Institute and the NextGen Consortium. At that time, only 11% of U.S. communities accepted paper cups in their recycling streams, but that rate is steadily increasing.

Sources herald FPI's work to grow paper cup acceptance for recycling, which picked up during the last five years. FPI President Natha Dempsey told Packaging Dive earlier this year that the association is “deliberate about our recovery work and making sure that we are using a demand pull system that starts with the end markets that want materials and are willing to utilize those materials.”

ReMa adding paper cups to its inbound specifications “illustrates a recognition that paper cups have the ability to be properly sorted at most dual and single stream MRFs along with robust end market demand,” Dempsey said via email Tuesday.

Fiber recycling rates have appeared somewhat flat in recent years, and industry participants frequently debate ways to boost it. Cups are one way to fill a gap between recycled fiber supply and demand, GPI says.

It is “essential to expand the range of paperboard packaging materials that are recovered and recycled," GPI said in Monday’s news release. "Instead of letting billions of paper cups — a high-quality, underutilized fiber source — go to waste, what if we could put them back into circulation?"