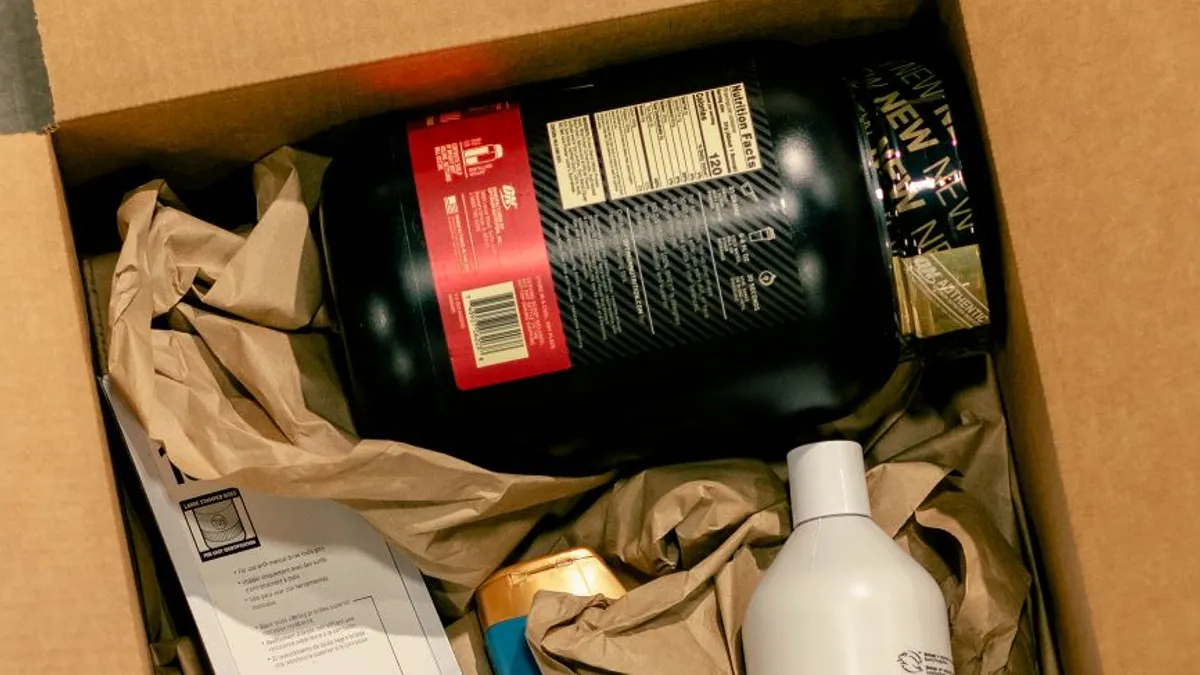

Amazon is swapping out plastic air pillows for paper-based protective packaging. Furniture company West Elm has replaced plastic cushioning with fiber-based, curbside recyclable packaging. As these and other major retailers aim to improve the recyclability of their e-commerce packaging, manufacturers are responding by diversifying offerings for protective and void fill materials.

Protective packaging — whether it’s inside, outside or the box itself — “is ripe for disruption,” said Matthew Wright, founder and CEO of Specright, a tech platform with solutions for rightsizing packaging and more.

Packaging suppliers are aiming to balance their portfolios and innovate their offerings to ensure they can offer packaging that meets customer needs — whether the priority is sustainability, protection, competitive cost or a combination of factors.

“By giving customers choice and offering a multitude of solutions, they're somewhat insulated from mix shifts that occur,” said Jeff Cloetingh, managing director and partner with L.E.K. Consulting's packaging sector.

Peanuts to pillows to paper

The protective packaging sector has expanded and evolved alongside e-commerce, which has grown from making up less than 1% of overall U.S. retail sales in 2000 to about 16% today, according to U.S. Census Bureau data.

Expanded polystyrene foam “packing peanuts” were long a popular way to fill empty space inside a parcel but from a consumer experience standpoint, they were “a pain in the neck to get rid of,” Cloetingh said. They were bulky, didn’t always provide adequate cushioning for products shipped across long distances, and ultimately had to go in the trash, he said.

Packaging manufacturers and their customers started transitioning to air pillows, “a lightweight alternative” that created “a protective barrier around products without taking up much space,” Anna Perlina, consultant and managing partner at European packaging consulting firm Integrity Solutions, said in an email. The pillows decreased overall material usage and shipping costs, she said.

But the future of plastic air pillows is in question. Retailers have publicly committed to move away from air pillows, citing sustainability reasons.

Amazon announced in June that it had replaced 95% of plastic air pillows in its North American deliveries with paper filler. The packaging is made of 100% recycled content and can be recycled at home, said Pat Lindner, vice president of mechatronics and sustainable packaging at Amazon. By the end of this year, the online retailer intends to fully eliminate plastic air pillows in the region.

Amazon’s move could set a precedent for other retailers to follow suit, and packaging suppliers are preparing for a future in which void fill looks different than its current state.

“There are certainly some pressures on plastic-based, non-recyclable, in-the-box protective packaging,” Cloetingh said.

Air pillows remain common, especially in the U.S., and pillow manufacturers haven’t felt too much impact from retailers’ changes or had to pivot just yet, Wright said. Cloetingh similarly expressed that “the complete elimination of air pillows has not yet occurred,” adding that he doesn’t see protective packaging or void fill ever going away.

Sealed Air executives described “weakness” in the company’s protective packaging business and said void fill is a “deteriorating sector” during their most recent earnings call. The company is vulnerable to mix shifts from plastic to paper, because fiber-based packaging makes up just 10% to 15% of its sales, compared to the material comprising 40% of sales at competitors, according to an August report from Truist Securities’ Michael Roxland, senior paper and packaging analyst.

In response, manufacturers are moving away from “providing one type of protective packaging solution” and evolving their business models into “multi-substrate, multi-solution,” Cloetingh said. “It may be shifting from one product that they make to another product that they make.”

In fact, for Amazon, “some of the suppliers that originally supplied us with our air pillows are supplying us with paper filler,” Lindner said in an email.

Even if packaging suppliers see decreased demand for plastic pillows, the overall protective packaging market is robust, thanks to e-commerce’s continued expansion, Wright said.

“The baseline business is growing so much,” Wright said, with a good portion of growth coming from fiber and alternative products.

Evolving alternatives

The shift to more sustainable packaging is not as simple as plastic to paper.

“Plastic elimination, material usage minimization, and CO2 reduction do not necessarily go hand in hand when switching from film to paper,” Perlina said.

For curbside recyclability, paper is much more widely accepted for recycling than film. But Pregis, which offers air cushions in addition to protective paper, indicated in a recent blog post that plastic pillows weigh less, producing a lower carbon footprint for shipping.

That’s why packaging manufacturers are exploring a variety of materials. Air pillows can be made from 100% recyclable fossil-based plastic, compostable film made from bio-feedstock or other biodegradable materials, Perlina said.

Experimental solutions include Orora’s work with Flexi-Hex to distribute a recycled fiber protective sleeve in a honeycomb design. Other packaging and material suppliers, like Ino, have dabbled in protective packaging made of silkworm cocoons.

“You see a lot of niche cool stuff, which typically starts the innovation curve, but you’ve got to make sure that's something that could be sustained,” Wright said. It can’t be cost prohibitive, either. Supplies of niche materials may be limited, which makes the material difficult to source and the products costly to make, trickling down from packaging supplier to consumer.

“When [consumers are] buying a product, you're not buying it to pay for all the protective packaging,” Wright said.

As an example, Wright cited shredded paper fill made from recycled boxes, which requires a steady stream of used boxes that can be put through a shredding machine. “You’ve got to think backwards,” he said. “Can you sustain the feed or supply base that you need?”

Retailers and their packaging suppliers are also working to better match box dimensions to the product, reducing the amount of protective packaging needed.

“As an online shopper myself, I notice that in many cases, air pillows compensate for the inappropriately large e-commerce boxes,” Perlina said.

West Elm brought new equipment into its packing facilities to rightsize boxes. The results, according to the retailer, were improved efficiency, lowered transportation emissions and a better customer experience with less waste to unpack.

Amazon has similarly seen less waste following its initiatives. The online retailer said it has used AI to determine the most efficient packaging for each item, calculating that it has avoided more than 3 million tons of packaging material worldwide since 2015.

The practice of rightsizing does create “an inherent headwind” for internal packaging manufacturers, “because you just need less material to fill the void,” Cloetingh said.

Some packaging suppliers have turned their focus to paper padded mailers, an option meant to be recycled curbside and that eliminates plastic, boxes and void fill altogether. Fiber mailers are an area where Sealed Air views an opportunity to close “sustainability-related gaps in our portfolio,” said CFO Dustin Semach during the recent earnings call. Such mailers could recoup lost volumes in Sealed Air’s protective packaging business, and the business is less capital intensive, Truist noted.

Heavy, oddly shaped or fragile products may require various solutions for protection during shipping, whether using crumpled paper, bubble wrap or foam in place, Cloetingh said.

Ultimately, the least sustainable option is when a product arrives damaged, retailers often say and Cloetingh echoed. That could result in product waste or the consumer returning the product. It could also mean a retailer needs to reship the item with new void fill, adding to packaging material and emissions.

Amazon has found its paper-based filler “offers the same, if not better, protection to products than plastic air pillows,” Lindner said. “As of now, we’re not seeing any negatives.”