In 2024, the packaging industry will build off of a year of persistent destocking, C-suite shakeups, thousands of manufacturing layoffs and dozens of deals consolidating certain parts of the industry, among other challenges and changes.

Companies’ geographic footprints and the industry landscape at large may look a little different, as familiar storylines around extended producer responsibility, material swaps and other sustainable packaging solutions also continue to advance.

These are some of the top factors to watch in the year ahead. Which other packaging industry trends are you tracking? Send us an email at [email protected].

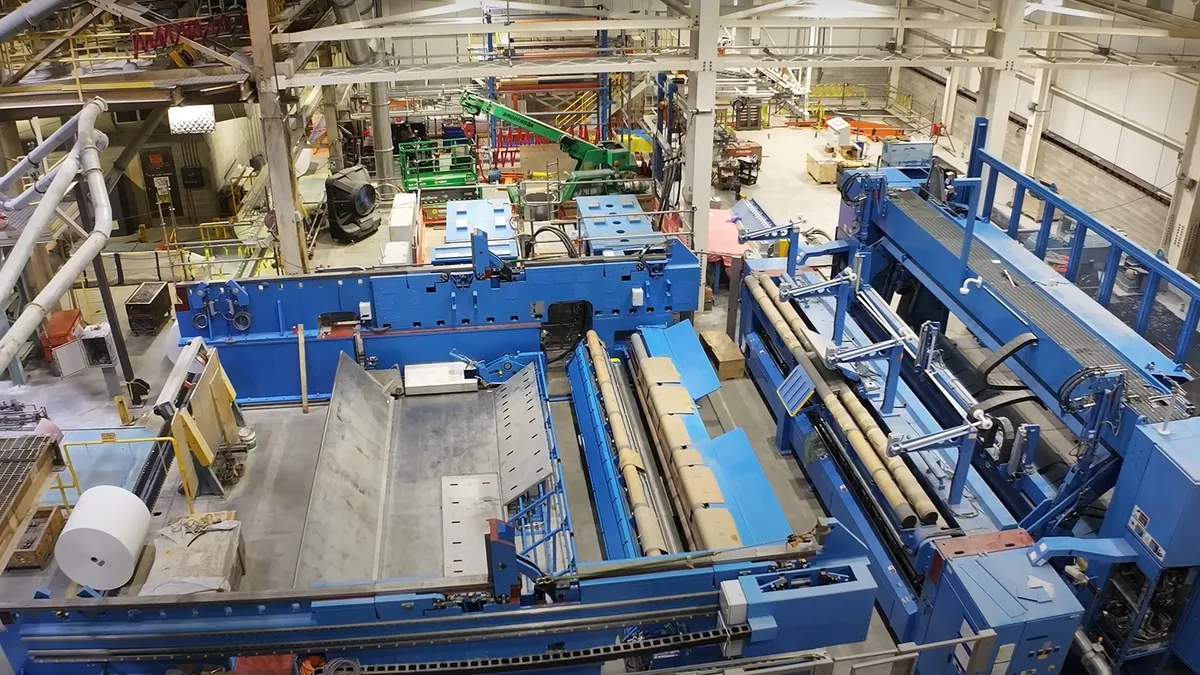

Manufacturing footprints shift as producers balance facility closures with openings

With at least 9,000 packaging jobs affected by facility closures in 2023, changes in companies' manufacturing footprints are evident. But with numerous equipment upgrades and facility openings on the docket for 2024 and beyond, many are pondering what the net result will be as packaging producers work to balance the openings and closures with demand.

Company executives repeatedly referred to shifting footprints as part of “optimization” or “rationalization” plans during a bumpy 2023. Berry Global closed at least 20 facilities and WestRock's Tacoma, Washington, mill closure affected 400 people. Ball decided to permanently nix plans to build a beverage can plant in North Las Vegas. Equipment shutdowns included Graphic Packaging International permanently decommissioning a coated recycled paperboard machine at its mill in Kalamazoo, Michigan, and International Paper announcing production cessation for a pulp machine in North Carolina and another in Florida.

But footprint shifts aren't solely due to consolidation or facility idling resulting from lagging demand. Some legacy equipment shutdowns coincide with new equipment startups and greater automation to boost operational efficiencies.

It's also not just a matter of shrinking: Many companies are adding space. Fiber-centric businesses, especially recycled grades, are on an opening blitz.

North American containerboard capacity already expanded significantly from 2020 to 2023. Fifteen new mills came online, which will affect supply and demand dynamics going forward, Bill Moore, president of consulting firm Moore & Associates, said in October.

Some 2023 openings included Cascades' recycled containerboard plant in Bear Island, Virginia, International Paper and Pratt Industries' corrugated packaging facilities, WestRock's corrugated box plant in Longview, Washington, and York Container Company rounding out the year with the startup of its corrugated box plant in Elgin, Illinois.

Experts predict the fiber facility opening spree, particularly for recycled grades, will continue in the near term. For example, the new Total Fiber Recovery plant in Chesapeake, Virginia, is expected to begin producing recycled pulp this month, notes Chaz Miller of Miller Recycling Services. Another new Pratt facility is slated to begin production late this year in Peach County, Georgia. And Graphic Packaging's new $1 billion, 640,000-square-foot coated recycled paperboard mill in Waco, Texas, is expected to begin operations in 2026.

Influenced by inflation, consumer purchasing adapts

Cost-conscious consumers' purchasing habits could signal a packaging demand renormalization following years of turbulence, but packaging companies are starting the year with price increases. At the very least, “recovery” from 2023's demand and sales valleys is anticipated, as evidenced by the Institute for Supply Management's December prediction that manufacturing revenues will increase, with growth expected to accelerate in the second half of 2024.

Following a glut of consumer spending, packaging company executives began pointing to consumers pulling back on purchases in 2023, particularly later in the year. Primarily driven by economic factors such as inflation, packaging executives noticed consumers not just making fewer purchases, but also “trading down” and purchasing more cost-effective pack sizes and store brand products instead of branded or luxury goods.

Pactiv Evergreen CEO Michael King said in May that consumers are deprioritizing certain pricier products as part of the consumption shift — including eating at home more or choosing fast food over sit-down restaurants. Silgan executives said consumers who trade down by purchasing more groceries instead of prepared food actually benefit sales for certain packaging sectors, such as metal food containers. During recent earnings calls, Amcor executives cited continued weak consumer demand, and those at Graphic Packaging and Sonoco confirmed the “cautious consumer” is influencing sales.

Persistent inflation concerns continue to create uncertainty about the specifics of the industry's recovery trajectory. Referencing GPI's attempt to pull up from the lows of destocking and demand uncertainty, CEO Michael Doss explained in November that “recovery is just not linear; it tends to be a little bit lumpier than anybody says."

Inflation is proving to be a sticky problem that heavily influences both consumer purchasing and packaging companies' business decisions. In late 2023 and early 2024, fiber packaging companies including International Paper, Packaging Corporation of America and WestRock announced their first corrugated price increases in years. And Sonoco will implement at least a 6% price hike on all converted paperboard products.

While inklings of recovering demand emerged in the fourth quarter of 2023, Fastmarkets still called the price increases — which either took effect Jan. 1 or will begin on Feb. 1 — a “bold move questioned by most in the marketplace.” Greif began 2024 by announcing a price hike on uncoated recycled board, prompting Michael Roxland, senior paper and packaging analyst at Truist Securities, to issue a commentary noting that “inflationary pressures could also spur producers to increase prices on certain grades of virgin boxboard.”

Major policies get closer to becoming reality

U.S. states and international governmental bodies are poised to be some of the most influential standard-setters this year on the future of packaging materials, labeling and extended producer responsibility through finalizing or implementing buzzy new policies — and that’s without considering fresh legislation sure to be on the table in 2024.

California made waves in waste policy in recent years, including with SB 343, which seeks to crack down on recyclability labeling, and SB 54, an EPR law impacting plastic packaging producers. Implementing those laws is a long process; CalRecycle rang in the new year detailing materials that could be covered and sharing highly anticipated draft rules for the EPR program. California also selected a producer responsibility organization.

Other states including Colorado, Maine, Maryland and Oregon will also continue preparatory or implementation activities for their own takes on EPR for packaging.

Focus on per- and polyfluoroalkyl substances, or “forever chemicals,” has been increasing nationally. States are leading on regulating PFAS in packaging. Among the most common type of state-level packaging laws coming into force this year — including in Colorado, Hawai’i, Maryland, Minnesota, Rhode Island and Washington — are bans on PFAS in certain food packaging, which raises the stakes on finding alternatives, including to provide moisture and grease barriers for paper packaging.

Internationally, sweeping new rules are expected to enter final negotiations in the European Union. The regulation is poised to have major implications for stricter recyclability standards and spur shifts from single-use packaging to reuse. And already in January, the government of Canada announced it launched a consultation on establishing a registry that would require plastic producers to report on the plastic they place on the market and track its life cycle.

Scrutiny increases on end-of-life issues

How to best manage materials after use, whether through disposal, recycling or other avenues — and how to communicate those discard instructions — remains a central challenge for packaging. The area lacks standardization, and debate could intensify this year.

The packaging industry is focusing more on designing for recyclability to improve recycling in general. New scannable codes and apps seek to help.

The Federal Trade Commission’s guidance on packaging labeling and environmental marketing more broadly aims to bring some modernized clarity; the current review is still ongoing after issues of recyclability took the spotlight in 2023.

Since the Green Guides’ last major review in 2012, compostable packaging has become mainstream and part of many companies’ 2025 sustainability goals, but it has also led to some contamination at compost sites and in recycling streams. Now, leading organizations are seeking greater uniformity in how compostable and non-compostable packaging is designed, colored and labeled to create more distinguishable visual signals. At the same time, California is advancing implementation of SB 343.

Chemical recycling practices — and how they’re incorporated into recycling claims via mass balance and perceived by consumers — is another emerging area of concern for the Green Guides to address. More packaging companies have highlighted chemical recycling operations’ potential to be an outlet for hard-to-recycle flexible packaging, and also a source of feedstock to replace some use of virgin materials. Amcor and SEE, for instance, both have partnerships with ExxonMobil.

2025 plastics targets loom

2024 could be the year countries reach a United Nations-driven agreement to “end plastic pollution,” although consensus-building has been predictably challenging. And ever since the circular economy-focused Ellen MacArthur Foundation and UN Environment Programme launched the “Global Commitment” in 2018, the year 2025 has loomed large.

More than 1,000 organizations have signed on to the voluntary pact to make all plastic packaging recyclable, compostable or reusable by 2025, a target that many brand commitments and the U.S. Plastics Pact goals mirror. The EMF commitment also calls for eliminating problematic or unnecessary plastic packaging, moving from single-use to reuse models where relevant, decreasing the use of virgin plastic in packaging and increasing the share of postconsumer recycled plastic.

As crunch time for the stated deadline approaches, a recent five-year progress report from EMF said “the world remains significantly off track.” The report also showed reusables only account for 1% of major brands’ plastic packaging.

Now, both 2025 and a potential international agreement are less than a year away. Sustainability reports from the past year show how brands and packaging manufacturers have made progress in some areas yet backslid in others. They’ve reported common challenges around coming up with solutions for flexible packaging, adequately sourcing recycled content and in some cases actually increasing virgin plastic use.

In one example, SEE, the company formerly known as Sealed Air, announced last year it was already reassessing its 2025 goal in light of insufficient recycling infrastructure for flexible plastics and challenges around food-grade recyclate.

Incorporating chemically recycled plastic appears to be an increasingly popular, yet controversial, strategy, and new capacity for mechanically recycled material should be coming online this year, notably from Republic Services. As the march to lower plastic reliance continues, fiber-based packaging companies are also trying to further capitalize on the switch.

Falling short of stated sustainability metrics would not be a first for the industry; still, while the target 2025 deadlines are voluntary in nature, unity on that year does make it prominent and increase the pressure.

Editor’s note: This story has been updated with the news that CalRecycle announced the selection of a PRO.