Dive Brief:

- Confusion remains over whether PET thermoforms can be recycled curbside in the U.S., but they are increasingly collected, according to speakers at the Packaging Recycling Summit in Anaheim, California, last week.

- On Nov. 1, Rumpke Waste & Recycling will begin accepting thermoforms in select markets, with more expected in the future, announced Jeff Snyder, senior vice president of recycling. This is possible thanks to artificial intelligence technologies at Rumpke’s new MRF in Columbus, Ohio, which opened in August.

- The National Association for PET Container Resources said the U.S. has excess capacity to reclaim PET and meet postconsumer recycled content demand, but “we do not have the material to feed it domestically,” said Megan Moore, program director. “Today, we could scale up PET reclamation almost 30% if we had the supply, and a big part of that is reclaiming the thermoforms that are recyclable.”

Dive Insight:

PET thermoforms are molecularly similar to PET bottles — the most recycled plastic packaging item — but differences make them less desirable to certain players along the value chain and therefore less accepted for recycling, NAPCOR’s Moore said.

“They are good feedstocks for some end markets,” she said, but certain issues, such as contamination from labels, render them not appropriate for every end market.

“We do have quite a lot of recycling capacity within the U.S. that handles thermoforms on a daily basis,” Moore said, clarifying that reclaimers can handle either segregated thermoforms or those commingled with PET bottles. While NAPCOR estimates less than 60% of U.S. communities have access to curbside thermoform recycling, keeping it under the “widely recycled” threshold, “that's still quite a lot of access,” she said.

There aren’t enough bottles to go around to meet growing PCR demands, and thermoforms can be an “untapped source” for that PCR, said Zach Muscato, corporate sustainability manager at Plastic Ingenuity.

NAPCOR estimates that thermoforms comprise roughly a quarter to a third of the reclaimed PET market, coming in at about 1.8 billion pounds annually compared with PET bottles’ 6.5 billion pounds. A Foodservice Packaging Institute study last year estimated that the U.S. and Canada only recovered about 9% of thermoforms generated in 2018.

Public access to curbside PET thermoform recycling varies widely by state, Muscato said. For example, he explained that access in California is around 90% while it’s zero in neighboring Oregon.

“You see that across the U.S. In the Northeast, you have pretty good acceptance. In the Midwest, it's been challenging — until Jeff's company stepped up,” Muscato said. “A lot of it has to do with access, and I believe a lot of that has to do with end markets.”

Snyder supported that end markets idea, explaining that a lot of Rumpke’s PET material purchasers focus on bottle-to-bottle recycling and therefore strip out from PET bales the colored bottles, cups and thermoforms. Bales that contain more than 10% thermoforms can get rejected, he said.

The labels on thermoforms are a sticking point and a leading reason the product is often viewed less favorably than PET bottles, Muscato said.

“The labels on thermoforms tend to be very hard to remove. Oftentimes, there is a fiber component to those labels, so those labels will contaminate the PET recycling stream,” he said. “A big part of what we do when we design a package is not just look at the thermoform that we're designing, but look at the package holistically.”

Many labels are applied to thermoforms at the point of sale, such as for deli items, which further complicates the issue, Moore said. Overall, “the recycling compatibility of thermoforms in the bottle stream has been a concern for probably about 15 years,” she said.

Rumpke’s new Columbus facility has been testing the viability of separating the different PET grades with its AI technologies. Just five years ago, this wasn’t possible, Snyder said, illustrating how quickly recycling capabilities are changing and how AI has become a “game changer.”

“Technology is growing to the point where we are able to go deeper into the waste stream than we've ever had before,” Snyder said. “Now, because I can take a picture of it by shape, color and size, and tell that [near infrared] optical scanner to blow the thermoform off the belt but leave the PET bottle, now I can segregate them.”

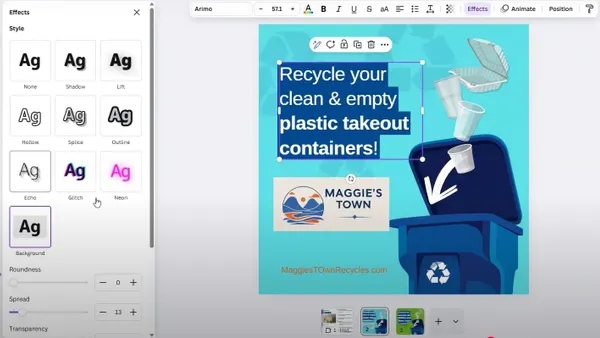

With the change to the accepted items list, Rumpke is also changing its messaging to consumers: “Our accepted items list now has pictures of thermoforms on it,” Snyder said. “We don’t use numbers. We use pictures, we use descriptions. We try to make it as simple as we possibly can.”

Eastman Chemical Co. is partnering with Rumpke to take its thermoforms and colored PET for chemical recycling. Rumpke is also exploring other end markets as opportunities arise, Snyder said. Adding additional end markets is crucial to creating a better thermoform recycling ecosystem by ensuring MRFs and reclaimers are incentivized to participate, Muscato said.

“We’ve seen a lot of growth in the last three to four years of thermoform-only bales,” he said. For example, berry supplier Driscoll’s has said it strictly wants thermoform-derived PET to increase the amount of postconsumer recycled content in its clamshells, which has helped to incentivize reclaimers to sort that material. Extended producer responsibility legislation and ecomodulation plans are also considered to be a potential driver for using more thermoforms as PCR material.